Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SY-20

Brand: SKYIMG

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Paper Coating, Plastic Coating, Car Paint

Instructions: Spray, Brush

Status: Powder Coating

Types Of: Adsorbent

Classification: Chemical Auxiliary Agent

Application Field: Coating Auxiliary Agents,Leather Auxiliary Agents,Paper Chemicals,Textile Auxiliary Agents

Status: Powder Coating

Packaging: 25kgs/Bag

Productivity: 10000 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Feature

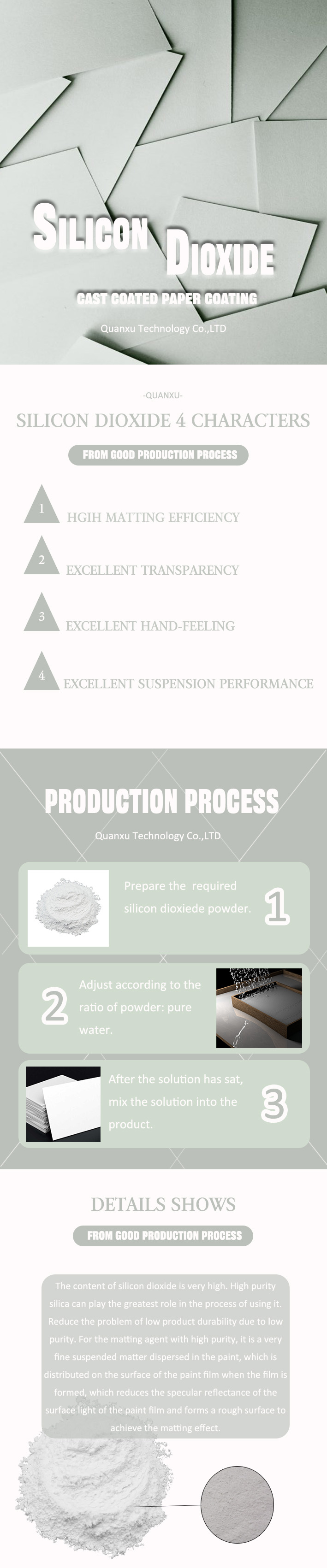

Silica dioxide powder, also known as silica, is a common additive used in various industries, including the paper and

ink industry. It is used to improve the properties of paper and ink, such as enhancing the hand-feeling, improving

printability, and increasing the opacity of the ink.

When selecting a silica dioxide powder for paper ink, it is important to consider the following factors:

1. Purity: Look for a high-purity silica dioxide powder to ensure that it does not contain any impurities that could affect the

quality of the paper or ink.

2. Particle Size: The particle size of the silica dioxide powder can affect its performance in paper ink. Smaller particle sizes

generally provide better dispersion and improved hand-feeling.

3. Surface Area: Silica dioxide powders with a larger surface area can enhance the ink's ability to adhere to the paper,

resulting in improved print quality.

4. Porosity: Silica dioxide powders with a higher porosity can help in absorbing ink and reducing bleeding, resulting in sharper

and more defined prints.

5. Compatibility: Ensure that the silica dioxide powder is compatible with the other components of the ink formulation to avoid

any adverse reactions or compatibility issues.

6. Safety: Consider the safety aspects of the silica dioxide powder, such as whether it is free from harmful substances, meets

regulatory requirements, and has appropriate safety data sheets available.

It is recommended to consult with suppliers or manufacturers who specialize in providing silica dioxide powders for the paper

and ink industry. They can provide specific recommendations based on your requirements and offer samples for testing and

evaluation.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Inkjet Receptive Coating For Cast Coated Paper

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.