Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SY-20

Brand: Quanxu

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Paper Coating, Plastic Coating, Car Paint

Instructions: Spray, Brush

Status: Powder Coating

Types Of: Adsorbent

Classification: Chemical Auxiliary Agent

Application Field: Coating Auxiliary Agents,Leather Auxiliary Agents,Paper Chemicals,Textile Auxiliary Agents

Status: Powder Coating

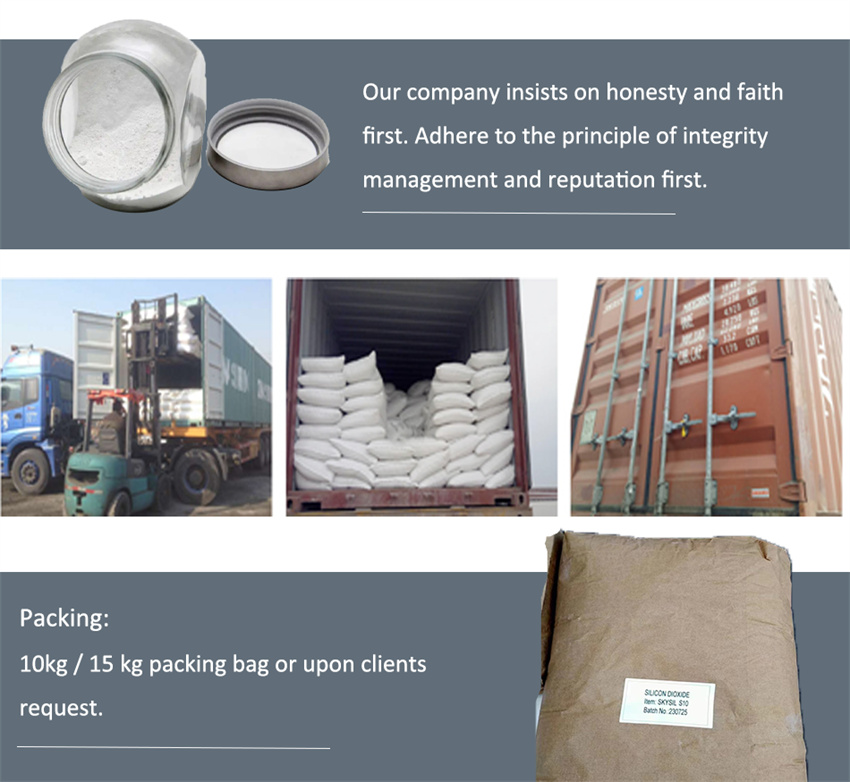

Packaging: 25kgs/Bag

Productivity: 10000 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Features:

Silica Powder is widely used in various industries, including paper coatings. It is known for its high absorbency and fast-drying

properties, making it an ideal additive for fast-dry paper coatings.

Here are some key features and benefits of using 99% content silica powder in fast-dry paper coatings:

1. Absorbency: Silica powder has a high surface area and porosity, allowing it to absorb liquids quickly. In paper coatings,

this property helps to absorb the liquid components of the coating, reducing drying time significantly.

2. Fast drying: The high absorbency of silica powder enables it to absorb moisture from the coating quickly. This helps in faster

evaporation of the liquid components, resulting in faster drying times for the paper coatings.

3. Improved print quality: Fast-dry paper coatings with silica powder allow for better ink absorption and reduced smudging. This

leads to improved print quality, sharper images, and enhanced color vibrancy.

4. Reduced production time: By using silica powder in fast-dry paper coatings, manufacturers can reduce the production time.

The faster drying process allows for quicker handling and packaging, increasing overall production efficiency.

5. Cost-effective: Silica powder is a cost-effective additive for fast-dry paper coatings. Its high absorbency and fast-drying properties

help reduce energy consumption during the drying process, leading to cost savings.

6. Enhanced durability: Silica powder in paper coatings can improve the durability and longevity of the coated paper. It helps to

strengthen the coating, making it more resistant to smudging, abrasion, and moisture damage.

7. Compatibility: Silica powder is compatible with various coating formulations, making it suitable for a wide range of paper

coating applications. It can be easily incorporated into existing coating recipes without causing significant changes in the

formulation.

In summary, 99% content silica powder is an excellent choice for fast-dry paper coatings. Its high absorbency, fast-drying

properties, improved print quality, cost-effectiveness, and compatibility make it a valuable additive in the paper coating industry.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Inkjet Receptive Coating For Cast Coated Paper

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.