Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: H-903

Brand: Quanxu

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Paper Coating, Plastic Coating, Car Paint

Instructions: Spray, Brush

Status: Powder Coating

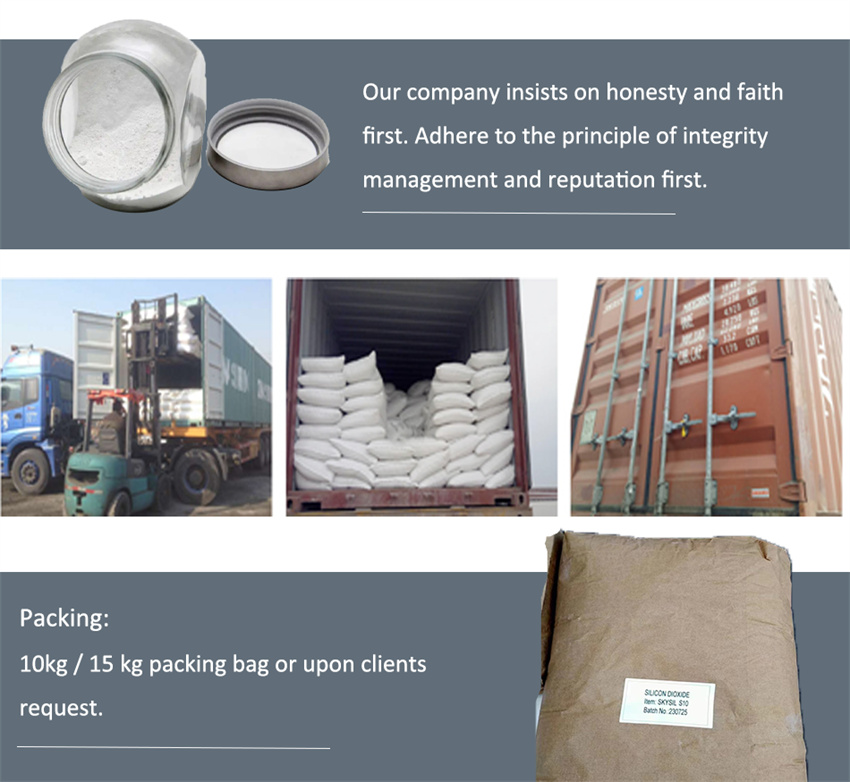

Packaging: 25kgs/Bag

Productivity: 10000 Ton/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

The new method for preparing silicon dioxide mainly uses non-metallic minerals and their extensions as silicon sources

and adopts precipitation method to prepare silicon dioxide. The key technology is to transform crystalline silicon dioxide

and silicate into amorphous silicon dioxide. The raw materials mainly include wollastonite, opal, halloysite, olivine,

serpentine, kaolin, hard kaolin, coal gangue, fly ash, etc.

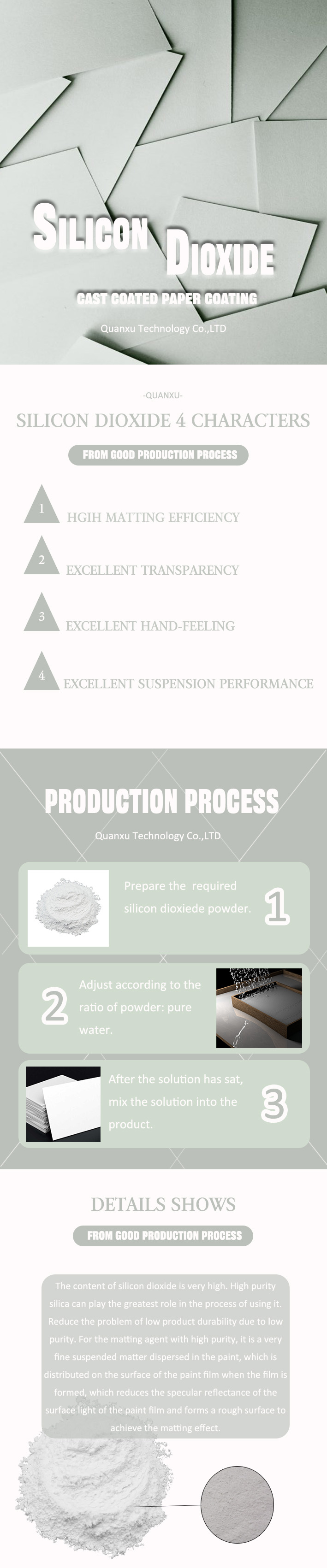

Silicon dioxide

This paper focuses on the process technology of preparing silicon dioxide using kaolin or hard kaolin, coal gangue or fly ash

as raw materials

(1) Using kaolin or hard kaolin as raw materials

First, crush the kaolin or hard kaolin to 50~60 mesh, then roast it at 500~600℃ for 2 hours, then mix the roasted soil with 30%

industrial hydrochloric acid at a ratio of 1:2.5 (weight), acid-leach at about 90℃ for 7 hours, and obtain silicon dioxide after

neutralization, filtration, washing and drying. The product quality meets the GB10507-89 standard; at the same time, obtain

high-efficiency water purifier polyaluminium chloride. The reaction formulas for roasting and acid leaching are as follows:

Roasting: Al2O3•2Si02•2H20—>Al2O3•2Si02+2H20

Acid leaching: Al2O3•2Si02+6HCl+9H20—>2AlCl3•6H20+2SiO2

(2) Using coal gangue or fly ash as raw materials

First, crush the coal gangue or fly ash to a particle size less than 120 mesh, and then divide it into two steps:

One-step production of sodium silicate: mix the crushed coal gangue or fly ash with soda ash in a weight ratio of 1:50, and then melt

it at high temperature (1400~1500℃, 1 hour), extract it with water (above 100℃, 4~5 hours), filter out impurities, and concentrate the

filtrate to 45~46 degrees Baume to obtain sodium silicate.

Two-step production of silicon dioxide: first prepare sodium silicate into water glass solution (modulus of 2.4~3.6, SiO2 content of 4~10%),

then acid-soak in 5~20% sulfuric acid (28~32℃, 8~16 hours), then heat to 80℃, stir, adjust pH value to 5~7, mature for 20 minutes, then filter,

wash, dry and sort to obtain silicon dioxide. The silicon dioxide is active and high in purity.

| Type | H-903 | Loss on drying(105℃,2hrs),% | ≤5.0 |

| Content of Sio2 (dry based) %, | ≥99.0 | Ignition loss(1000℃,2Hrs),% | ≤6.0 |

| Porosity ml/g | 1.8-2.0 | Whiteness,% | ≥90.0 |

| Oil absorption, g/100g | 260-300 | PH(5% Liquor) | 6-7 |

| Particle Size, um(Malvent,D50) | 6.0-7.0 | Surface Treatment | None |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Inkjet Receptive Coating For Cast Coated Paper

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.