Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SKYELEC

Brand: SKYELEC

Place Of Origin: China

Status: Used

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Core Components: Plc, Engine, Pressure Vessel, Gear, Pump

Warranty Period: 1 Year

Core Selling Point: High Productivity

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Construction Works, Energy &Amp; Mining

Packaging: Cardboard Box / Cardboard Box + Wooden Fram

Productivity: 1000 Unit/Units per Month Fluo

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000000 Pieces/Year

Certificate: ISO9001/SGS

HS Code: 8516909000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT

Materials of Construction

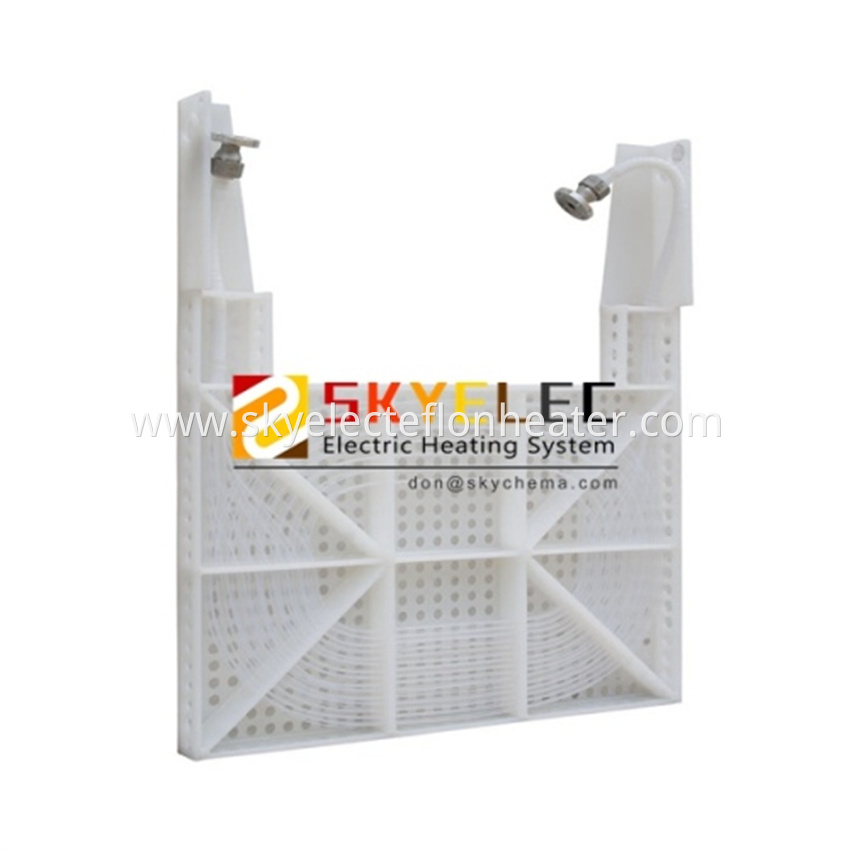

Materials of construction for the Immersion Coil Heat Exchanger consists of either polypropylene, PVDF, or PTFE for the

frame, and either FEP, PFA, or PTFE for the tubing. Custom designs may include other fluoropolymer materials such as

ETFE, ECTFE or PCTFE.

Advantages

The advantages of our heat exchanger products over alternative designs include:

Low operating cost - The operating cost includes maintenance such as inspection, cleaning, downtime, and repair. This is

primarily due to the relatively simple design that involves no plastic welding joints

No weld joints - Unlike metals that are subject to more rapid degradation under aggressive pickle bath conditions, Fluorotherm’s

heat exchangers withstand aggressiveness

Off the shelf repair kits - In case of an unlikely event of accidental tube damage, these kits enable a quick repair of the tubing

No tube bundling - The strong tubing coils are optimally spaced so acid flow and therefore heat transfer is maintained without

fouling.

Constant operating efficiency - Fluoropolymers such as PTFE, FEP or PFA, are inherently “non-stick”, so fouling by scale deposition

is minimized, assuring a constant operating efficiency that does not decrease over time. No other material, except natural diamond, inhibits sticking of the pickle bath particulates more than fluoropolymers

Immersion Coil Heat Exchangers

Manufactures H2 conductive tubing coil heat exchangers for use in restricted spaces in new and retrofit applications. This product provides between 2.3 to 2.7times the heat transfer capability of clear, natural tubing coils. The heat transfer rate is similar to steel

without the corrosion attack susceptibility. It is also used in baths where electrical static discharge is a major concern. This product has

undergone several iterations of improvement in properties and is unique to our line of heat exchanger offerings.

PVDF/PFA/PTFE Heat Exchangers Immersion Coils

| PTFE(Fluorpolymer) Heating and cooling coils | |||||

| Exchange area Sq.Ft | Connections Inch | Length In./mm | Width In./mm | Thickness In./mm | Model No. |

| 5.5 | 3/4 FNPT | 11.5(292) | 11.5(292) | 2(51) | XC-12-12 |

| 11 | 3/4 FNPT | 15.5(394) | 15.5(394) | 2(51) | XC-16-16 |

| 16.5 | 3/4 FNPT | 17.5(445) | 17.5(445) | 2.36(60) | XC-18-18 |

| 22 | 3/4 FNPT | 19.7(500) | 15.7(400) | 2.36(60) | XC-20-16 |

| 27.5 | 3/4 FNPT | 19.7(500) | 19.7(500) | 2.36(60) | XC-20-20 |

| 33 | 3/4 FNPT | 23.5(597) | 23.5(597) | 2.36(60) | XC-24-24 |

| 38.5 | 3/4 FNPT | 27.5(700) | 23.5(597) | 2.36(60) | XC-28-24 |

| 44 | 3/4 FNPT | 27.5(700) | 27.5(700) | 2.76(70) | XC-28-28 |

| 49.5 | 3/4 FNPT | 31.5(800) | 31.5(800) | 2.76(70) | XC-32-32 |

| 55 | 1 FNPT | 33.9(860) | 33.9(860) | 2.76(70) | XC-34-34 |

| 60.5 | 1 FNPT | 35.5(900) | 31.5(800) | 2.76(70) | XC-36-32 |

| 66 | 1 FNPT | 35.5(900) | 33.9(860) | 2.76(70) | XC-36-34 |

| 71.5 | 1 FNPT | 35.5(900) | 35.5(900) | 2.76(70) | XC-36-36 |

| 77 | 1 FNPT | 39.5(1000) | 33.9(860) | 3.15(80) | XC-40-34 |

| 83.5 | 1 FNPT | 39.5(1000) | 35.5(900) | 3.15(80) | XC-40-36 |

| 89 | 1 FNPT | 39.5(1000) | 39.5(1000) | 3.15(80) | XC-40-40 |

| 94.5 | 1 FNPT | 39.5(1000) | 39.5(1000) | 3.15(80) | XC-41-41 |

| 99 | 1 FNPT | 43.3(1100) | 39.5(1000) | 3.15(80) | XC-43-40 |

| 104 | 1-1/2 FNPT | 43.3(1100) | 39.5(1000) | 3.54(90) | XC-44-40 |

| 110 | 1-1/2 FNPT | 45.3(1150) | 39.5(1000) | 3.54(90) | XC-45-40 |

| 115 | 1-1/2 FNPT | 47.2(1200) | 39.5(1000) | 3.54(90) | XC-47-40 |

| 120 | 1-1/2 FNPT | 47.2(1200) | 39.5(1000) | 3.54(90) | XC-48-41 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Electric Heater > Coil & Heat Exchangers

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.