Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SKYELEC

Brand: SKYELEC

Place Of Origin: China

Status: Used

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Construction Works, Energy &Amp; Mining, Other

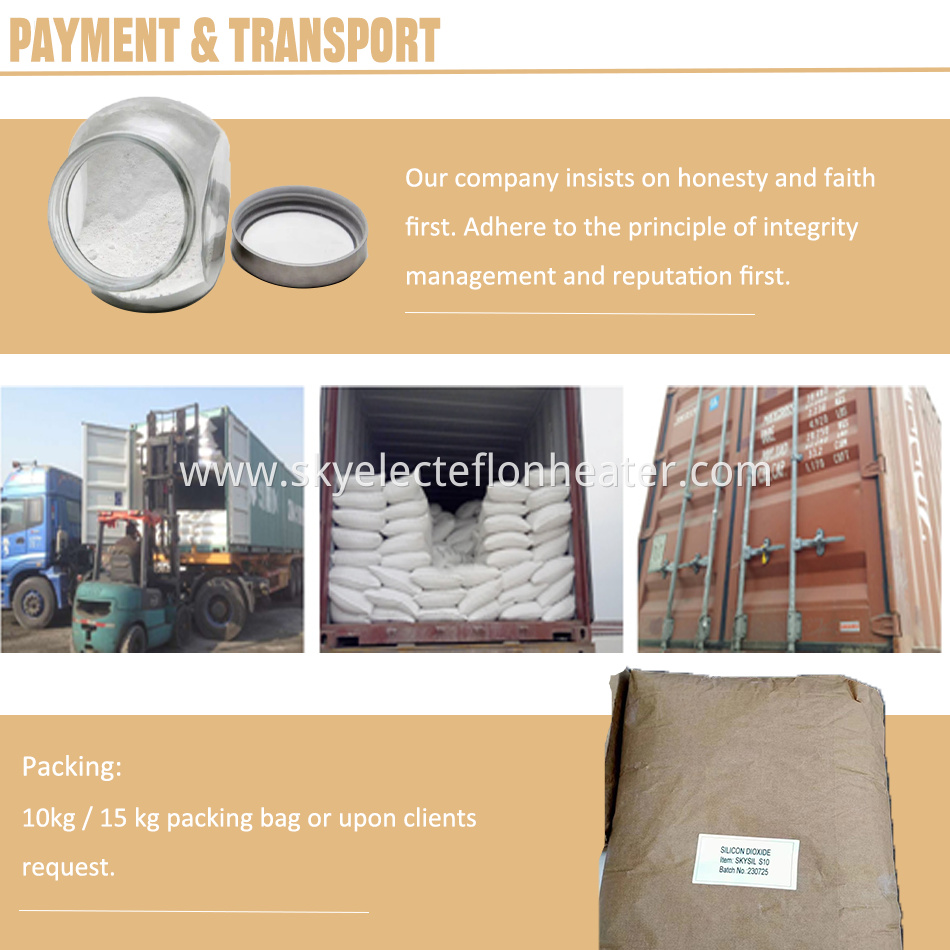

Packaging: Cardboard Box / Cardboard Box + Wooden Fram

Productivity: 1000 Unit/Units per Month Fluo

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000000 Pieces/Year

Certificate: ISO9001/SGS

HS Code: 8516909000

Port: Guangzhou,Shenzhen,Shnaghai

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

Introduction:

SKYELEC PTFE heat exchanger products are made of American DuPont PFA, FEP, and PTFE thin tube materials. Multiple

positioning plates are used to pass through. Both ends are firmly welded with the same material joints. Coiled into U, W, L,

straight. Beam type, round. The use of high temperature and corrosion resistant PP pure plate or PVDF as the protection frame

can effectively protect the heat exchanger tube bundle from mechanical damage. The heat exchanger as a whole is designed

and installed on the side or the bottom of the working groove. The interfaces at both ends of the heat exchanger are stainless

steel (304,316) flange type or PP, PVC joints; the interface diameter can be matched according to the diameter of your steam,

hot water or cold water pipeline.

Main technical parameters of heat exchanger:

A. PTFE heat exchanger products use Φ9, Φ6, Φ5, Φ4, Φ3 and other tube bundles and flanges arranged by honeycomb holes

and integrally welded. The protective frame is made of corrosion-resistant PP pure plate to shape and position the tube bundle

Easy to use and install, clean and beautiful, the interface is stainless steel (304,316) flange type or PP, PVC joints. Use steam

(heat-conducting oil or hot water) for heating; use cooling water (ground water, tap water, well water, frozen water) to cool down.

b. Product temperature range: -150 ~ 260 ℃; working pressure: steam≤0.5Mpa; refrigerant≤1.5Mpa.

c. Capillary heating, thin surface wall, non-sticky surface, small caliber, high pressure resistance, good temperature resistance and softness.

d. Product quality inspection: In the closed circuit system, the saturated steam is stabilized at 0.3Mpa for 1 hour; the cold-pressed

single tube is 1.4Mpa for 8 hours; the welding strength:> 50N / piece.

Features of PTFE heat exchanger material:

1. Because the fluoroplastic itself is non-sticky and self-cleaning, almost all media cannot adhere to its surface, and no dirt will be generated during use; therefore, the heat exchanger made of fluoroplastic has a certain self-cleaning function. At the same time, the fluoroplastic tube bundle is light in weight and there will be slight vibration during use.

2. The surface of the fluoroplastic heat exchange tube is smooth and the friction coefficient is small. Moreover, the fluoroplastic heat exchange tube is rich in elasticity compared to the metal heat exchange tube; the tube bundle of the fluoroplastic heat exchanger can make the fluid to be heated fully contact with the steam, and the surface The contact is large, which improves the heat exchange efficiency. Because the fluoroplastic itself is relatively light, the fluoroplastic heat exchanger is much lighter than the traditional metal

heat exchanger under the same operating conditions, which is conducive to transportation and installation.

3. With good thermal stability, flexibility, crack resistance and transparency, it can be continuously processed and can adapt to extremely high processing environments.

4. The product is soft and can be bent into any shape. However, the radius of curvature is ≥150㎜, and it has extremely high flame resistance; excellent electrical insulation and high-density non-polar materials have excellent dielectric properties, and no leakage and amphoteric electrodes are generated during the borrowing process.

5.Excellent anti-aging performance: the molecule can not interact with light-sensitive genes, ozone and ultraviolet rays, immersed in strong corrosive media, and exposed to harsh atmosphere for a long time; due to the corrosion resistance and wear resistance of fluoroplastic heat exchangers, it is not easy to accumulate Gray and many other advantages, has a high degree of chemical stability,

the molecular structure is completely symmetrical linear polymer without branched chain, the molecule does not have polarity, chemical stability is quite stable, strong acid, strong base, oxidant, oxide, king Long-term contact with water and other solutions is safe and stable, and can withstand the concentration of 0-100% boiling hydrofluoric acid.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Electric Heater > Coil & Heat Exchangers

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.