Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SL- 685

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Plastic Coating, Furniture Paint, Paper Coating, Electrical Insulating Varnish, Building Coating

Instructions: Brush

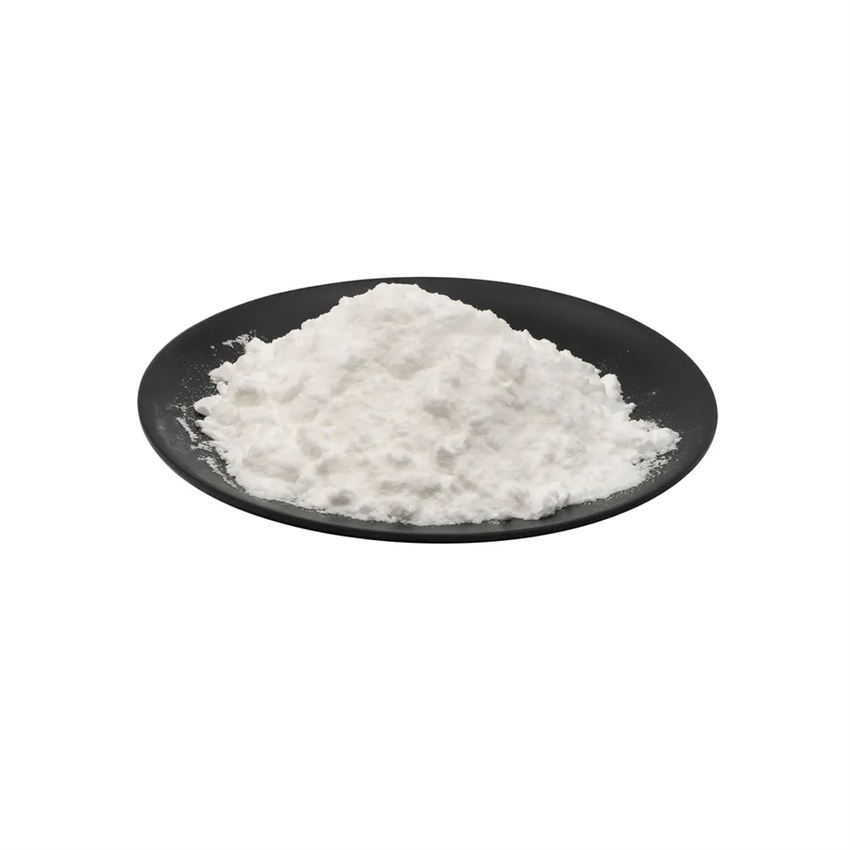

Status: Powder Coating

Productivity: 100000 Ton/Year

Certificate: SGS/ISO9001

Model No.: SL- 685

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized, 4.5 Ton Without Pallet.

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800 Ton/Month

Certificate: SGS/ ASTM / ROHS / REACH

HS Code: 2811229000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

High performance silicon dioxide can be used as a coating material for coil paint. Silicon dioxide is a type of nanoparticle

that has unique properties such as high surface area, high chemical stability, and good mechanical properties. These

properties make it an ideal material for use in coil paint.

Coil paint is a type of coating that is applied to coils of metal, such as aluminum or steel, before they are formed into various

products. The coating protects the metal from corrosion and enhances its appearance. High performance silicon dioxide can

be used as a filler material in the coil paint formulation to improve its properties.

The addition of silicon dioxide to coil paint can improve its scratch resistance, hardness, and durability. Silicon dioxide can

also improve the adhesion of the paint to the metal surface, which can prevent peeling or flaking of the coating over time.

Additionally, silicon dioxide can enhance the weathering resistance of the coil paint, which can prevent fading or discoloration

of the coating due to exposure to sunlight and other environmental factors.

Overall, the use of high performance silicon dioxide in coil paint can result in a higher quality and longer-lasting coating for

metal products.

When using matting agents, it is necessary to measure the fineness or Hegmann value of the coating to obtain information on

the dispersion. Since there are no rules for comparison with commonly used Matting Agent coating systems, the particle size value

can sometimes be defined as an acceptable method. The fineness is usually greater than 25 microns, such as silica matting agents.

Reducing the particle size value reduces the matting effect and increases the gloss.

Tips:

* Before you use it, please test and make sure the dosage before using according different formulations and conditions.

* Recommended dosage is 3% -5%.

| Item | SL-685 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | 99 | Porosity,ml/g | 1.8-2.0 |

| Oil absorption ml / 100g | 260-300 | Particle Size(Malvent),um | 6.0-7.0 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤6.0 | Whiteness≥ | 90 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Coil Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.