Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: HF-ME

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint

Instructions: Brush, Spray

Status: Powder Coating

Packaging: 125 Kgs/Plastic Drum.

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000 Ton/Year

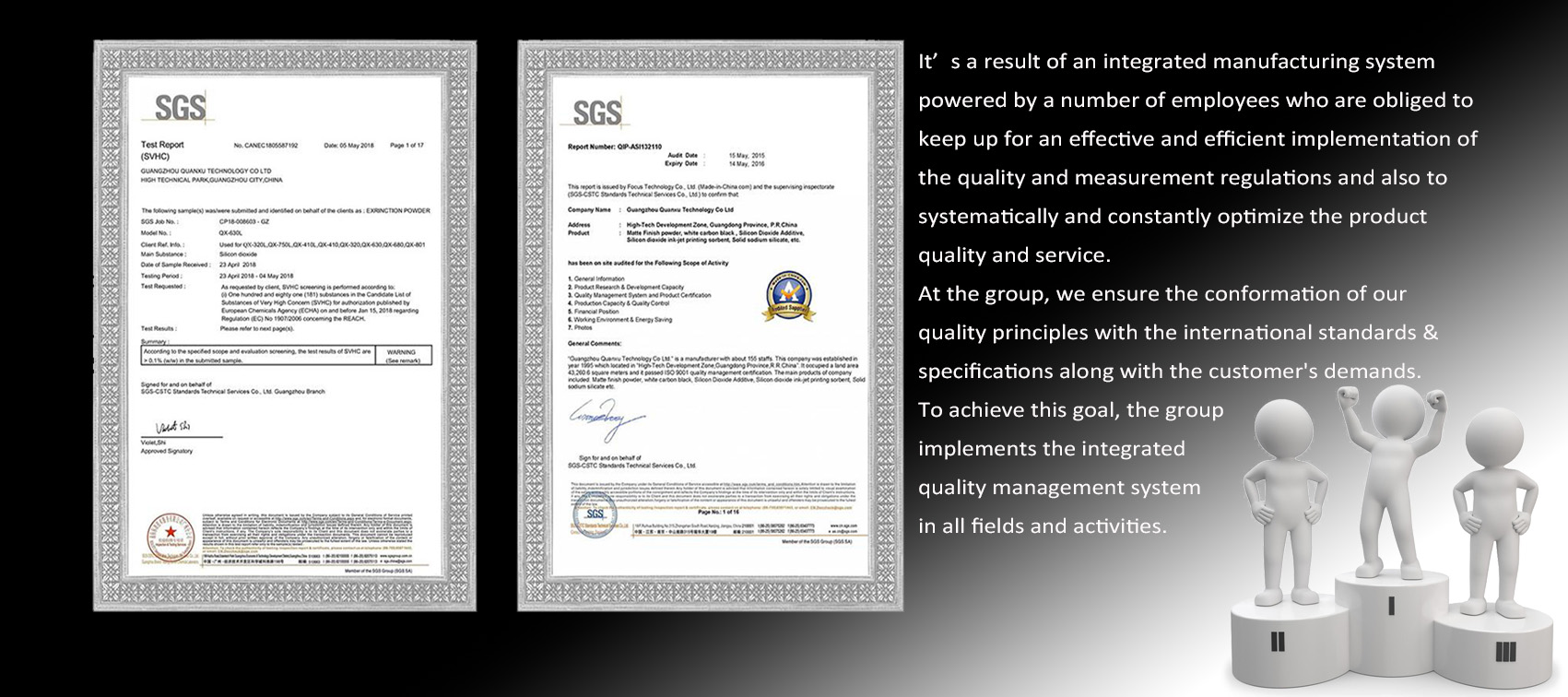

Certificate: SGS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Feature

Silicon dioxide, also known as silica, is a commonly used material in inkjet coatings. It is used to enhance the print quality

and durability of inkjet prints. Silicon dioxide is added to inkjet coatings to improve ink absorption, reduce bleeding and

smudging, and enhance color vibrancy.

When looking for a competitive price for silicon dioxide used for inkjet coating, there are a few factors to consider:

1. Purity: The purity of silicon dioxide can vary, and higher purity usually comes at a higher cost. Look for suppliers that

offer high-purity silicon dioxide to ensure the best performance in inkjet coatings.

2. Particle Size: The particle size of silicon dioxide can also affect its performance in inkjet coatings. Smaller particle sizes

generally provide better ink absorption and print quality. Suppliers offering a range of particle sizes can help you find the right

option for your specific application.

3. Quantity: The quantity of silicon dioxide you need can also impact the price. Larger quantities often come with volume discounts,

so it's worth considering your long-term needs and ordering in bulk if possible.

4. Supplier: Choosing a reputable supplier is crucial for getting competitive pricing. Look for suppliers with a track record of

providing high-quality silicon dioxide for inkjet coatings at competitive prices. Request quotes from multiple suppliers and

compare their prices and product quality before making a decision.

It's important to note that while price is a significant factor, it should not be the sole consideration when choosing silicon dioxide

for inkjet coating. The quality and performance of the material are equally important to ensure optimal print results.

Appearance Milk White solution Solid Content 35±1% PH Value 6-8 Viscosity 2800-3500 mpa.s Stability Six months

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Eco Solvent Inkjet Coating For Canvas

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.