Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

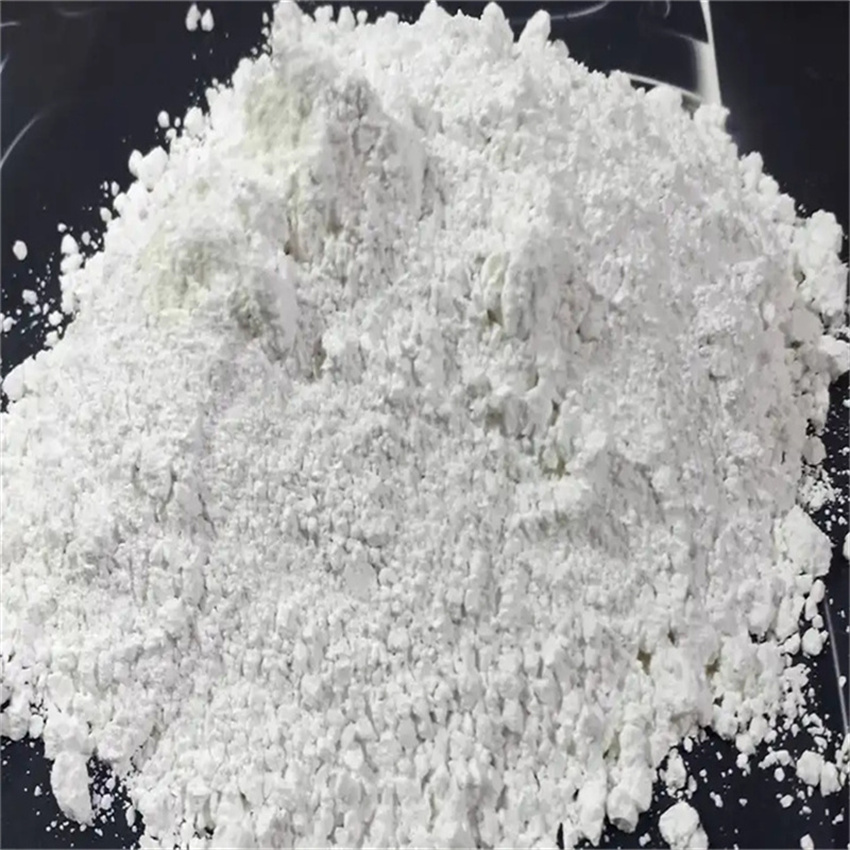

Model No.: SS-901

Brand: SKYSIL

Place Of Origin: China

Status: Powder Coating

Model No.: SS-901

Suitable Industry: Water Based Coatings

Productivity: 100000 Ton/Year

Certificate: SGS/ISO9001

Brand Name: SKYSIL

Packaging: 50 kgs/Drum, 225 kgs/Drum.

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Month

Certificate: SGS/ ASTM / ROHS / REACH

HS Code: 291611000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF

How can we identify the coatings for water based coatings?

As we all know that there are many coatings in the market. Then how can we identify different coatings? When the coatings

that is using water as solvent or dispersion medium all called water based coatings. Based on the adhesion types of coatings,

it can be departed into two types. One is the natural water based coatings which is made of nattural substance ot

minerals. The other is petrochemical water-based coatings based on synthetic resins (such as acrylic resins).

Why can we use silicon dioxide into water based coatings?

Natural silicon dioxide can be used as filler into the water based coatings. It can help to increase the adhesionability and

flow ability of the coatings which can enhance the coatings' durability and scratches resistance. The important part of

choosing silicon dioxide using into the water based coating is it must be detected by high purity testing. This can make sure the

silicon dioxide is applied into coatings in the largest extend. Besides, the datas like particle size and surface area of silicon

dioixde should be selected strictly to achieve the desired properties in the paint.

Its use can help to improve the durability, scratch resistance, and overall quality of the paint, resulting in a high-quality finish for automotive applications.

USING TIPS:

* Recommend dosage is 3%-8%. (Please adjust the dosage according to the actual product.)

* As different formulations and conditions, suggest the user to test and make sure the dosage before using.

| Item | SS-901 |

| Content of sio2(dry basis) %, | ≥99.0 |

| Porosity ml/g | 1.8-2.0 |

| Oil absorption, g/100g , g/100g | 230-280 |

| Particle Size, um(Malvent,D50) | 4.5-5.0 |

| Loss on drying(105℃,2Hrs) | ≤5.0 |

| Ignition loss(1000℃,2Hrs) | ≤11.0 |

| Whiteness | ≥90.0 |

| PH(5% Liquor) | 6-7 |

| Surface Treatment | Special |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Water Based Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.