Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SS-860

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Plastic Coating, Electrical Insulating Varnish

Instructions: Brush

Status: Powder Coating

Model No.: SS-860

Suitable Industry: UV Coatings

Productivity: 100000 Ton/Year

Certificate: SGS/ISO9001

Brand Name: SKYSIL

Packaging: 10 Kgs/Bags, 40 Kgs/Pallet, 4 Ton/ 10 Pallets.

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Month

Certificate: ROHS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Feature

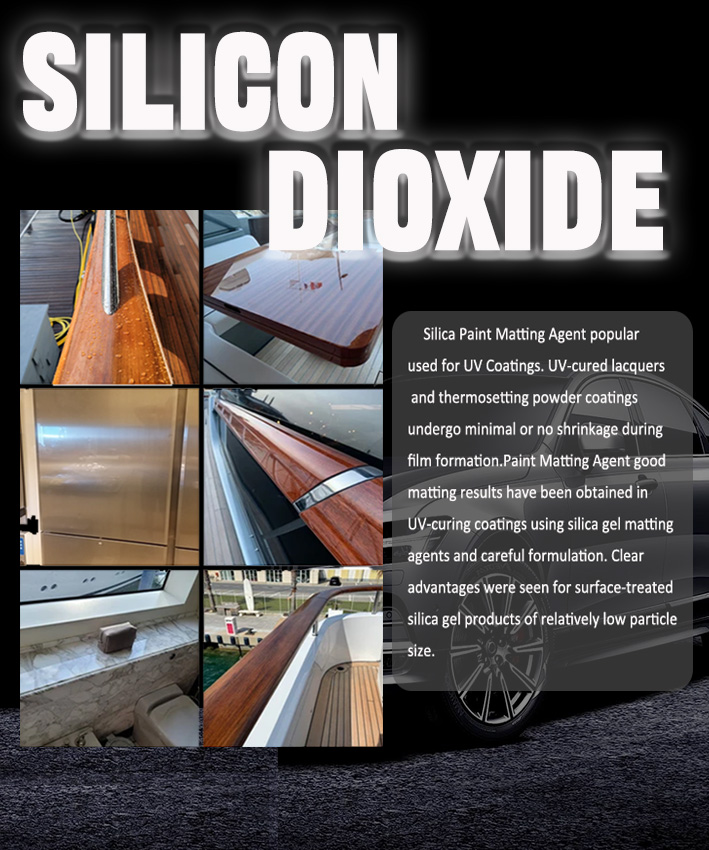

SiO2 powder can be used as a UV topcoat for various applications. SiO2, also known as silicon dioxide or silica, is

a commonly used material for its high refractive index, transparency, and UV resistance.

When used as a UV topcoat, SiO2 powder can provide several benefits:

1. UV Protection: SiO2 powder can act as a barrier against harmful UV radiation, protecting the underlying material from

fading, yellowing, or degradation caused by sun exposure.

2. Scratch Resistance: SiO2 powder can enhance the scratch resistance of the coated surface, providing a durable and

long-lasting protective layer.

3. Water Repellency: SiO2 powder can create a hydrophobic surface, repelling water and preventing water spots or stains

from forming on the coated surface.

4. Easy Cleaning: SiO2 powder can make the coated surface easier to clean by repelling dirt, dust, and other contaminants.

This can reduce the need for frequent cleaning and maintenance.

To apply SiO2 powder as a UV topcoat, it is typically mixed with a suitable solvent or binder to form a coating solution. The

solution can then be applied using various methods such as spraying, dipping, or brushing onto the desired surface. After

application, the coating is usually cured or dried to form a solid and protective layer.

It is important to follow the manufacturer's instructions and recommendations for proper handling, application, and curing of

SiO2 powder to achieve the desired UV topcoat properties.

USING TIPS:

* Recommend dosage is 3%-8%. (Please adjust the dosage according to the actual product.) * As different formulations and conditions, suggest the user to test and make sure the dosage before using.

| Item | SS-860 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | ≥ 99 | Whiteness | ≥ 90 |

| Porosity ml/g | ≥ 1.2 | Particle Size(Malvent),um | 5.0-6.0 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤13.0 | Oil Absorption g/100g | 140-180 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For UV Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.