Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SS-318

Brand: SKYSIL

Place Of Origin: China

Model No.: SS-318

Suitable Industry: Leather Coating

Productivity: 100000 Ton/Year

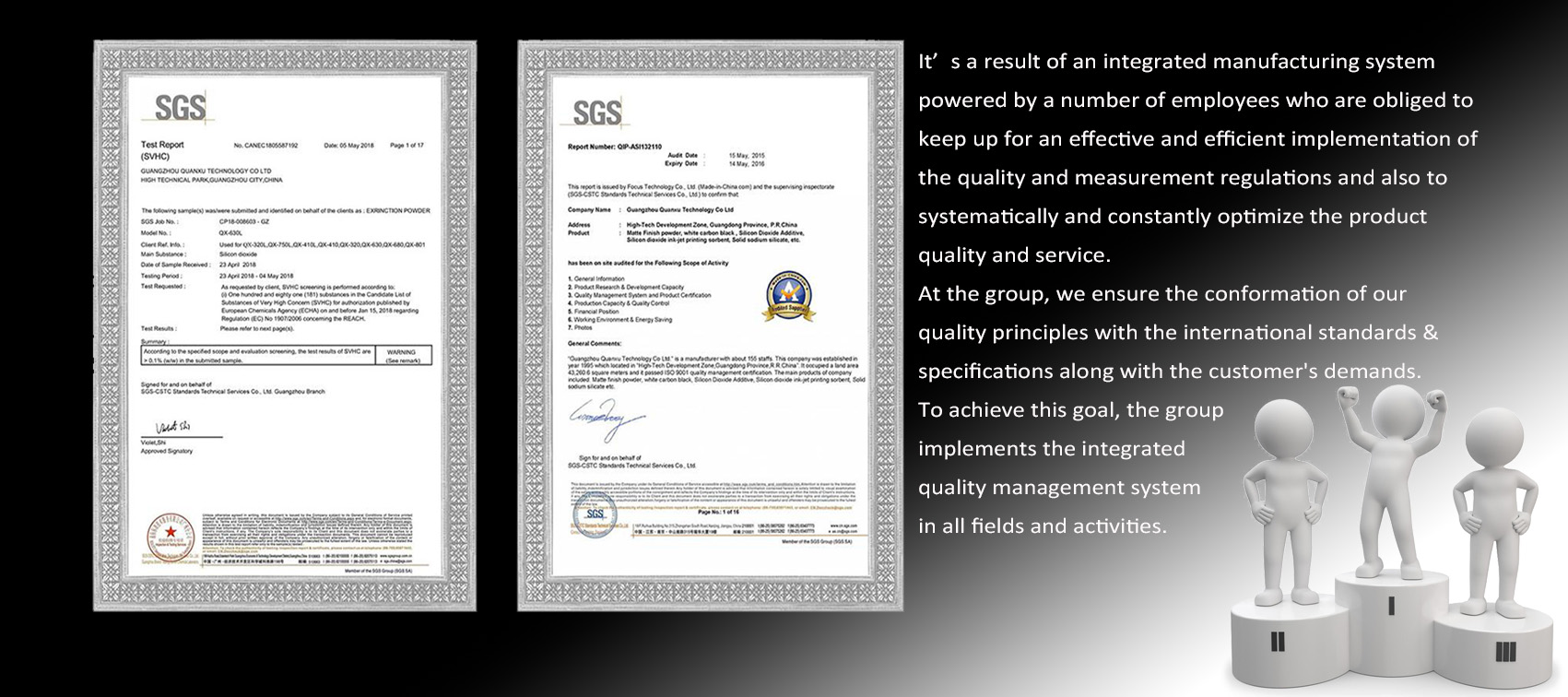

Certificate: SGS/ISO9001

Brand Name: SKYSIL

Packaging: 10kgs/bag,360kgs/Pallet,20fcl 3.6Ton With Pallet 4.5tTon Without Pallet

Productivity: 10000Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 800Ton/Month

Certificate: ISO/SGS

HS Code: 2811229000

Port: Shanghai,Guangzhou,Shenzhen

Payment Type: L/C,T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Feature

SiO2 powder is a common material used in ceramic coatings for cars and can be used as a protective layer for leather

surfaces as well. This material can provide a durable and long-lasting protective layer against UV rays, water, and other

environmental factors. It is recommended to use a leather conditioner before applying the SiO2 powder to ensure the

leather is clean and moisturized.

When selecting a SiO2 powder for black leather paint, several factors should be considered to ensure the desired appearance,

durability, and performance of the painted leather. Here's what to look for in the best SiO2 powder for black leather paint:

Pigment Dispersion: The SiO2 powder should disperse evenly in the paint formulation to ensure uniform color coverage

and prevent streaks or unevenness in the painted leather surface.

Color Stability: Choose a SiO2 powder that maintains color stability when mixed with black pigments and other additives

in the paint formulation. Color consistency is essential for achieving the desired shade of black and preventing color shifting

over time.

UV Stability: The SiO2 powder should be UV stable to prevent color fading or degradation of the black leather paint when

exposed to sunlight or other UV radiation. UV-stabilized SiO2 particles help maintain the color intensity and vibrancy of the

painted leather over time.

Adhesion: Surface-modified SiO2 particles can enhance adhesion to the leather surface, improving the durability and

longevity of the paint finish. Good adhesion ensures that the paint remains bonded to the leather and resists flaking or

peeling.

Flexibility: The black leather paint should remain flexible and resistant to cracking or creasing, even after repeated bending

or flexing of the leather surface. Choose a SiO2 powder that enhances the flexibility and elasticity of the paint film on the leather.

Abrasion Resistance: SiO2 additives can improve the abrasion resistance of the black leather paint, ensuring that it withstands

friction and wear without showing signs of damage or deterioration.

Water and Stain Resistance: Consider SiO2 powders that provide water and stain resistance to the black leather paint, protecting

it from spills, moisture, and other environmental contaminants. Water-repellent and stain-resistant properties help maintain the appearance and durability of the painted leather.

USING TIPS:

* Recommend dosage is 3%-8%. (Please adjust the dosage according to the actual product.) * As different formulations and conditions, suggest the user to test and make sure the dosage before using.| Item | SS-318 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | ≥ 99 | Whiteness | ≥ 90 |

| Porosity ml/g | 1.3-1.4 | Particle Size(Malvent),um | 3.0-3.5 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤6.0 | Oil Absorption g/100g | 260-320 |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Leather Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.