Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SL-685

Brand: SKYSIL

Place Of Origin: China

Main Ingredient: Acrylic, Epoxy, Nitrocellulose, Polyurethane

Application Field: Appliance Paint, Furniture Paint, Paper Coating, Plastic Coating, Electrical Insulating Varnish

Instructions: Brush, Spray

Status: Powder Coating

Suitable Industry: Industrial Coatings

Productivity: 100000 Ton/Year

Brand Name: SKYSIL

Certificate: SGS/ISO9001

Model No.: SL-685

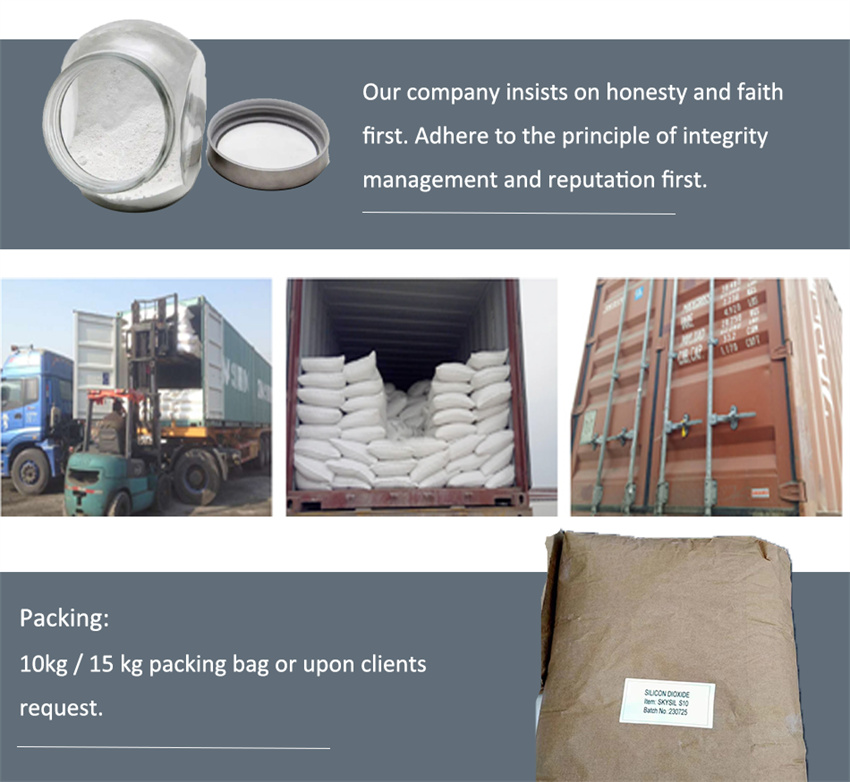

Packaging: 10 Kgs/Bag, 40 Kgs/Pallet, 4 Ton/10Pallets.

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10000 Ton/Year

Certificate: SGS

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Below are the points of silica Matting Agent can work in industrial paint.

1. Enhance scratches resistance and weather resistance. Silica matting agent is a super stable chemical object which can enhance paint's scratches

resistance and weather resistance to extend paint's using life.

2. Enhance paint transparent film's pyhsical properties. To adjust paint's hardeness,flexibility, scratches resistanceand other pyhsical properties can

adjust silica matting agent's types and using content.

3. Eco-friendly and cost benefit. Comparing with some organic matting agent, irorganic silica matting agent is moreeco friendly that is using in paint.

And at the same time, our silica matting agent has function of low cost which is wide use in industrial paint.

4. Antifouling performance. Silica matting agent has own self cleaning or antifouling property which can protect the coated surface from dirt, dust

and other contaminants. This helps maintain the cleanliness and appearance of industrial equipment, machinery and structures.

5. Optical clarity: In some applications, SiO2 powder can be used to maintain optical clarity and transparency in powder coating formulations.This is

very important for maintaining visibility of coated surfaces such as windows or transparent housings.

By incorporating high-grade SiO2 powder into industrial powder coatings, manufacturers can produce coatings with excellent performance,durability

and aesthetics for a wide range of industrial applications.

It should be noted that choosing the right type of silica matting powder (such as spherical, non-spherical, high refractive index, etc.) and the right amount

of addition are critical to achieving the desired performance. At the same time, factors such as compatibility with the substrate and the impact on the coating

process also need to be considered.

Tips:

* Before you use it, please test and make sure the dosage before using according different formulations and conditions.

* Recommended dosage is 3% -5%.

| Item | SL-685 | Brand | SKYSIL |

| Content of SiO2,(dry basis) %≥ | 99 | Oil absorption,g/100g | 260-300 |

| Porosity ml/g | 1.8-2.0 | Particle Size(Malvent),um | 6.0-7.0 |

| Loss on drying (105℃,2Hrs),% | ≤5.0 | PH | 6.0-7.0 |

| Ignition Loss(1000℃,2Hrs),% | ≤6.0 | Surface treatment | None |

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent > Matting Agent For Industrial Coatings

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.