Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: MS-780

Brand: SKYSIL

Classification: Chemical Auxiliary Agent

Place Of Origin: China

Material: Calcium Exchanged Silica

Color: White Powder

Application: Coil Coating, PCM Coating

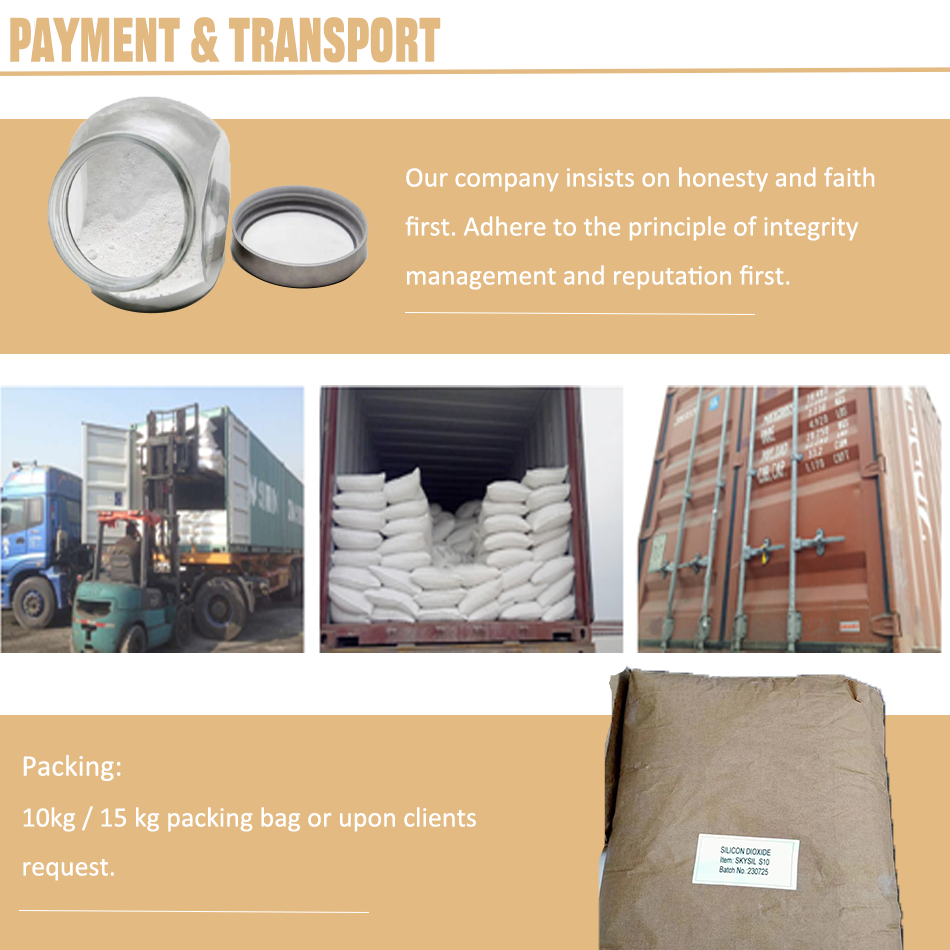

Packaging: 10 kgs/bag, 360 kgs/Pallet, 20 fcl 3.6 Ton With Palletized,

Productivity: 10000 Ton/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 1000 Ton/Month

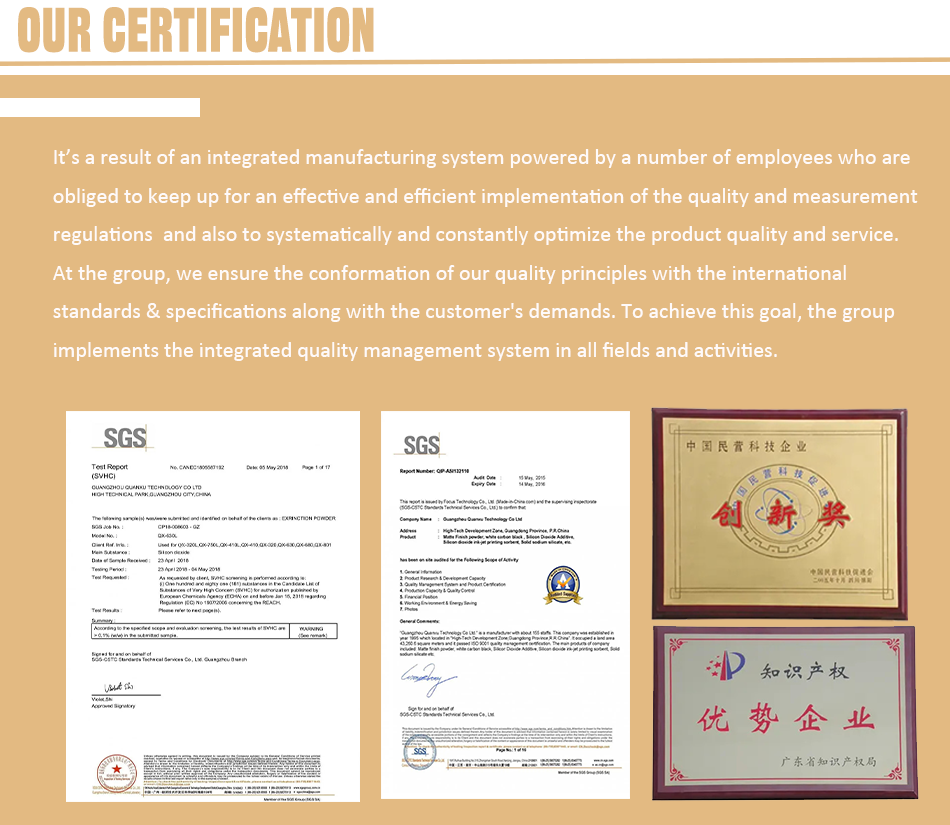

Certificate: SGS/ ASTM / ROHS / REACH

HS Code: 2811229000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Feature

Chemical grade silicon dioxide (SiO2) powder can be an effective choice as an anti-corrosive pigment in coatings due to its purity and specific properties. Here's why it's suitable for this application: Fine Particle Size: Fine particles of SiO2 powder can be uniformly dispersed within coating formulations, forming a dense and continuous barrier layer on the substrate surface. This barrier inhibits the ingress of moisture, oxygen, and corrosive agents, thereby reducing the likelihood of corrosion initiation and propagation. Chemical Inertness: SiO2 is chemically inert and resistant to a wide range of chemicals, acids, and alkalis. This property ensures that the anti-corrosive pigment remains stable and unaffected by exposure to corrosive environments, prolonging the service life of the coated substrate. Adhesion Enhancement: SiO2 particles can improve the adhesion of the coating to the substrate surface, promoting long-term adhesion and durability. This is particularly important in anti-corrosive coatings, where strong adhesion is necessary to prevent delamination and ensure effective protection. Versatility: Chemical grade SiO2 powder is compatible with a variety of coating resins, including epoxy, acrylic, polyester, and polyurethane. It can be easily incorporated into different coating formulations to tailor the properties of the anti-corrosive coating to specific application requirements. Cost-Effectiveness: While chemical grade SiO2 powder may have a higher initial cost compared to some other anti-corrosive pigments, its effectiveness and durability often make it a cost-effective choice in the long run. The superior protection it provides can help extend the maintenance intervals and service life of coated substrates, reducing overall lifecycle costs. Regulatory Compliance: Chemical grade SiO2 powder typically meets stringent regulatory standards for purity and safety, making it suitable for use in coatings intended for various applications, including those with strict regulatory requirements such as marine, automotive, and industrial coatings. Overall, chemical grade SiO2 powder offers several advantages as an anti-corrosive pigment in coatings, including high purity, fine particle size, chemical inertness, adhesion enhancement, UV stability, versatility, cost-effectiveness, and regulatory compliance. These properties make it a reliable choice for formulating durable and effective anti-corrosive coatings for a wide range of applications.

Technical Data Specification

| Item Type | MS-780 | |

| Content of sio2(dry based) %, | ≥99.0 | |

| Density(g/cm3) | 1.8 | |

| Oil absorption, g/100g | 50-70 | |

| Particle Size, um(Malvent,D50) | 3.0-3.5 | |

| PH(5% Liquor) | 7-9 | |

| Appearance | White Powder | |

Anticorrosion Pigments,

Inkjet Receptive Coating,

Matting Agent

Product Categories : Anti Corrosive Pigment

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.