Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: ZP-100-RG

Brand: SKYIMG

Material: Pvc, Pet, Pp

Types Of: Twist Film

Use: Decorative Film

Special Performance: Moisture Proof

Hardness: Soft

Transparency: Translucent

Place Of Origin: China

Sensitivity: Medium-sensitivity Film

Color Temperature: Daylight Type

Color: White: Surface: Matte

Printing Type: Front Print: Dry Time: Dry Instantly

Package: Neutral Export Package: Suitable Printer: Eco Solvent

Material: Polyester(PET): Base Thickness: 100 Microns

Compatible Ink: Eco Solvent: Suitable Printer: Solvent Printers

Usage: Visible Film

Imaging Type: Reversal Film

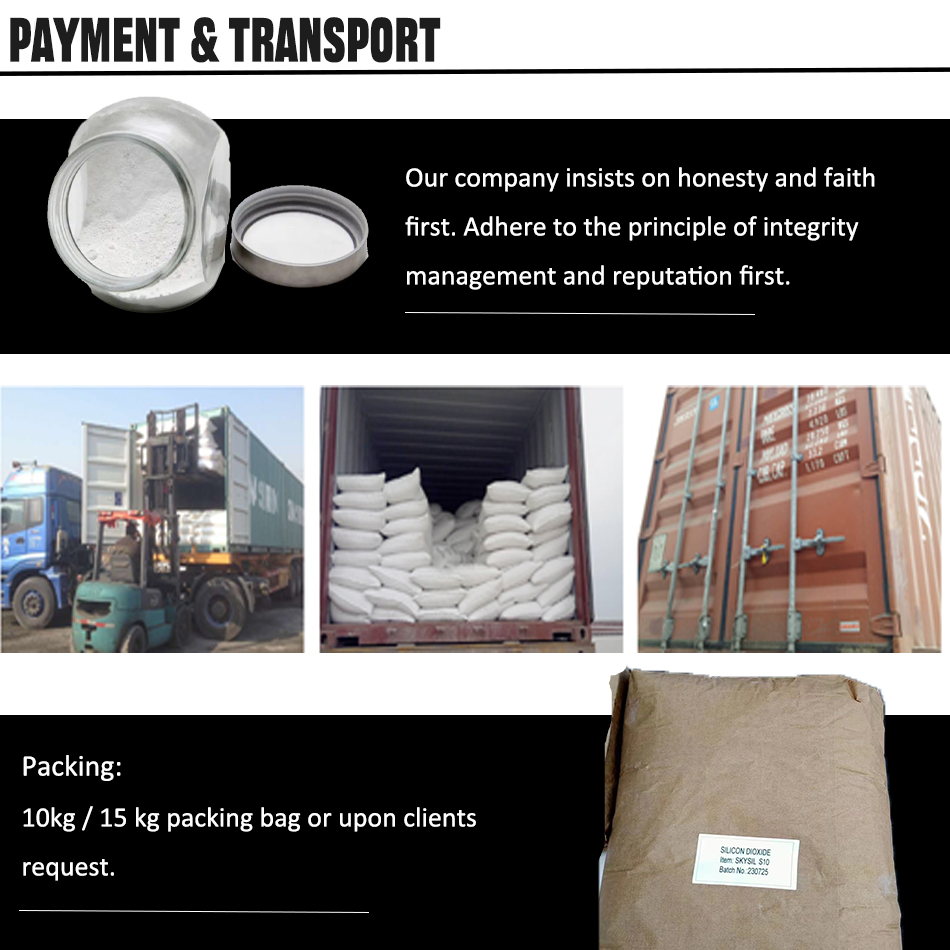

Packaging: 10 KGS / Bag

Productivity: 100000Square Meter/Square Mete

Transportation: Ocean,Land,Air

Place of Origin: China

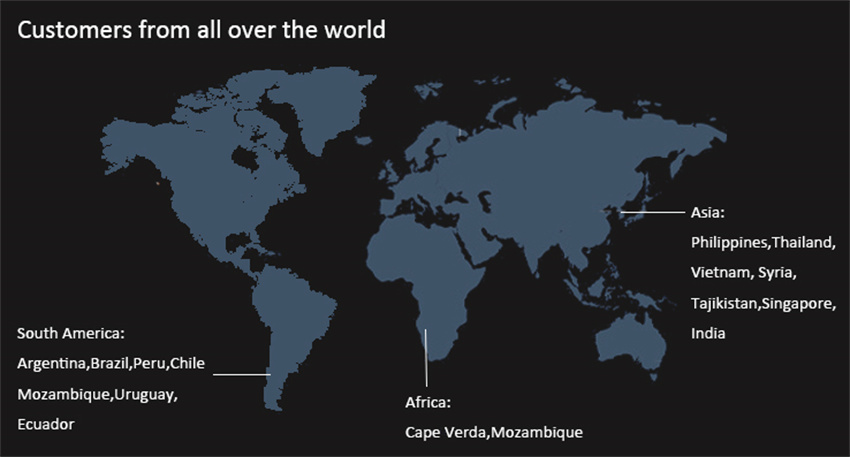

Supply Ability: 10000 Tons / Year

Certificate: SGS

HS Code: 3920690000

Port: Guangzhou,Shenzhen,Shanghai

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Silica Powder in paint protective films and paint additives is a functional filler commonly used in paint manufacturing. Here

is a detailed explanation of their role and use in coatings:

Silica powder (SiO2)

1. Enhanced performance: Silica powder can significantly improve the hardness, wear resistance, chemical resistance and

weather resistance of the coating. This is due to its high hardness and good chemical stability.

2. Improve leveling: Adding an appropriate amount of silica powder can improve the leveling of the paint and make the surface

of the coating smoother.

3. Improve hiding power: The high refractive index of silica powder helps to improve the hiding power of paint and reduce

the amount of paint, thereby reducing costs.

4. Anti-settling: In some coating systems, silica powder can be used as an anti-settling agent to prevent pigment particles

from settling during storage.

5. Ultraviolet shielding: Silica powder has a good shielding effect on ultraviolet rays, which helps to improve the aging resistance

of the coating.

In paint protective films, the use of silica powder is particularly critical. Protective films usually need to have excellent physical and

mechanical properties and environmental resistance, and the addition of silica powder can significantly improve these properties

in particular:

- Enhance the wear resistance of the protective film: The high hardness of silica powder can effectively increase the wear resistance

of the protective film and extend its service life.

- Improve scratch resistance: By improving the hardness and toughness of the film layer, silica powder can effectively reduce the

occurrence of scratches.

- Improved UV resistance: The UV shielding properties of silica powder help protect the substrate under the film from UV damage.

- Improve optical properties: By controlling the particle size and filling amount of silica powder, the transparency and gloss of the

protective film can be adjusted to meet the needs of different application scenarios.

In short, the application of silica powder in paint protective films and paint additives is mainly to optimize the overall performance

of paint products by improving the physical and mechanical properties of materials, improving appearance effects, and enhancing

anti-corrosion and anti-aging capabilities.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Product Categories : Matting Agent For PET Film > Matting Agent For Advertising Film

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.