Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

News

2023-11-02

Artur Palasz, Ph.D., Spektrochem, discusses the proper use of raw materials in formulations and how to avoid errors when scaling a formulation from lab to production scale, while ensuring maximum efficiency of time and energy

Today`s reality of latex paint formulations requires the supply to the R&D department (a paint manufacturer both in a large and a small company producing various latex paints) of technical materials showing the advantage of raw materials offered by a given supplier over the competition, as well as education of R&D employees in the use of specific raw materials in formulations through the so-called application studies, constituting case studies showing how a given raw material works in guideline formulations. Providing such tools is not only a competitive advantage of raw material suppliers, but also the ease of using the raw material in tests in specific projects, thanks to e.g. comparisons of effectiveness in various PVC ranges, performance with competitive additives, etc.

The consequence of this is the appropriate transfer to full-scale production, which must be relatively easy and made with all paint parameters set at the R&D stage. Translating a laboratory scale to a production scale is usually not extremely difficult, however, in this article we will focus on those raw material yields that, properly selected at the R&D stage, will later allow for the effective use of their full-scale potential and the production of high-quality latex paints.

Everyone in the paint industry knows that starting point formulations are standard support for launching raw materials on the market. However, today they are required to do a bit more than just be a list of ingredients from which the paint should be made. Today, market expectations and the competitiveness of raw material suppliers mean that, together with starting point formulations, application studies should also be provided showing how the raw material works in a given formulation and how the process of its adaptation to the formulation to be developed by the paint manufacturer should be conducted.

Application studies are a kind of guide which, for the formulator, is to be a signpost on how to use a given raw material so that its efficiency is maximally used, and how to later translate it into full-scale production. In this article, I will focus on two raw materials that are very much related to the transfer from lab to full scale and, contrary to the first glance, extremely related to each other, namely dispersants and defoamers.

Dispersing agents

In the starting point formulations, the quantities of raw materials are already defined. If we assume that they have been determined by laboratory tests, then how much is due to something. In the case of dispersants, this amount should result, firstly, from mill-base viscosity reduction, and secondly, from the effect of a specific dose selected by effective mill-base viscosity reduction on some other parameters, e.g. scrub resistance. Yes, a dispersant additive can (and usually does) affect the scrub resistance results. It can also affect the colour acceptance, storage stability or water sensitivity of the coating, however, in my article, let`s focus on scrub resistance as a key performance property.

In the starting point formulations, the defined dose of dispersant will be difficult to interpret without application studies showing how the dispersant performed at other doses. Such ladder studies provide an enormous amount of data and show not only the amount used to build a standard formulation, but where that dose was taken from.

Below are examples of such application studies with their short characteristics for dispersing agent. The tested dispersant was characterised by laboratory tests in a slurry formulation, which was then used to prepare latex paints.

The first characteristic of the dispersant was its effectiveness, defined as mill-base viscosity, i.e. the ability to lower the mill-base viscosity during grinding in the cowles dissolver. The slurry was composed of calcium carbonate and titanium dioxide (solid content 80% by weight) and the viscosity was tested after grinding with dispersant dosing in doses of 0.25%, 0.50%, 0.75%, 1.0% and 1.25% by weight calculated on active substances per solid content in the slurry. In general, we recommend expressing the amount of dispersant in this way, calculating in terms of active substances (active solids) and total pigments and fillers in the formulation. Of course, later in the final formulation, the amount is expressed in the dose of dispersant as supplied for the entire formulation, but it should be remembered that its amount is related to the above.

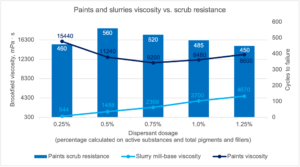

Figure 1. Summary of results of mill-base viscosity tests and the effect on paint viscosity and scrubbability depending on the dose of dispersant

The results of the viscosity measurements (ASTM D2196 method A by Brookfield viscometer, measurement directly from the metal Griffin beaker in which the slurry was prepared, immediately after its preparation) are shown in Figure 1. Each slurry was then combined with the acrylic polymer dispersion and other ingredients to form a PVC 37% acrylic paint formulation. For the prepared paints, after their stabilisation, viscosity measurements were also made as above, and their values are also shown in Figure 1. Finally, each of the prepared paints were applied to scrub panels and, after 7 days of conditioning at 23°C and 50% RH, were subjected to scrubbability tests according to ASTM D2486. Test results are also shown in Figure 1.

The discussed example of the application study provides the formulator with knowledge on the effectiveness of mill-base viscosity reduction, of course, together with the formulation in which it was used, as well as how the dispersant content affects the change in paint viscosity, which is the result of its impact on the thickeners and binder used in starting point formulations. The presented graph shows that the effectiveness of mill-base viscosity reduction increases practically linearly with the reduction of the dispersant dosing, which in turn is the opposite to the viscosity of the paint with its participation. In terms of scrubbability results, it can be seen that the sample with 0.5% of dispersant actives has the best result, which also correlates with the optimal viscosity of both slurry and paint.

Anticorrosion Pigments, Inkjet Receptive Coating, Matting Agent

Share to:

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.